Inner Mongolia Pusheng Environmental Protection Technology Co., Ltd. is located in Hohhot City, Inner Mongolia Autonomous Region. It mainly engages in the manufacturing and sale of special chemical products (excluding dangerous chemicals). Promotion services for new materials technology, energy-saving technology, and environmental protection technology; Sales of mechanical equipment, hardware products and electronic products, etc.

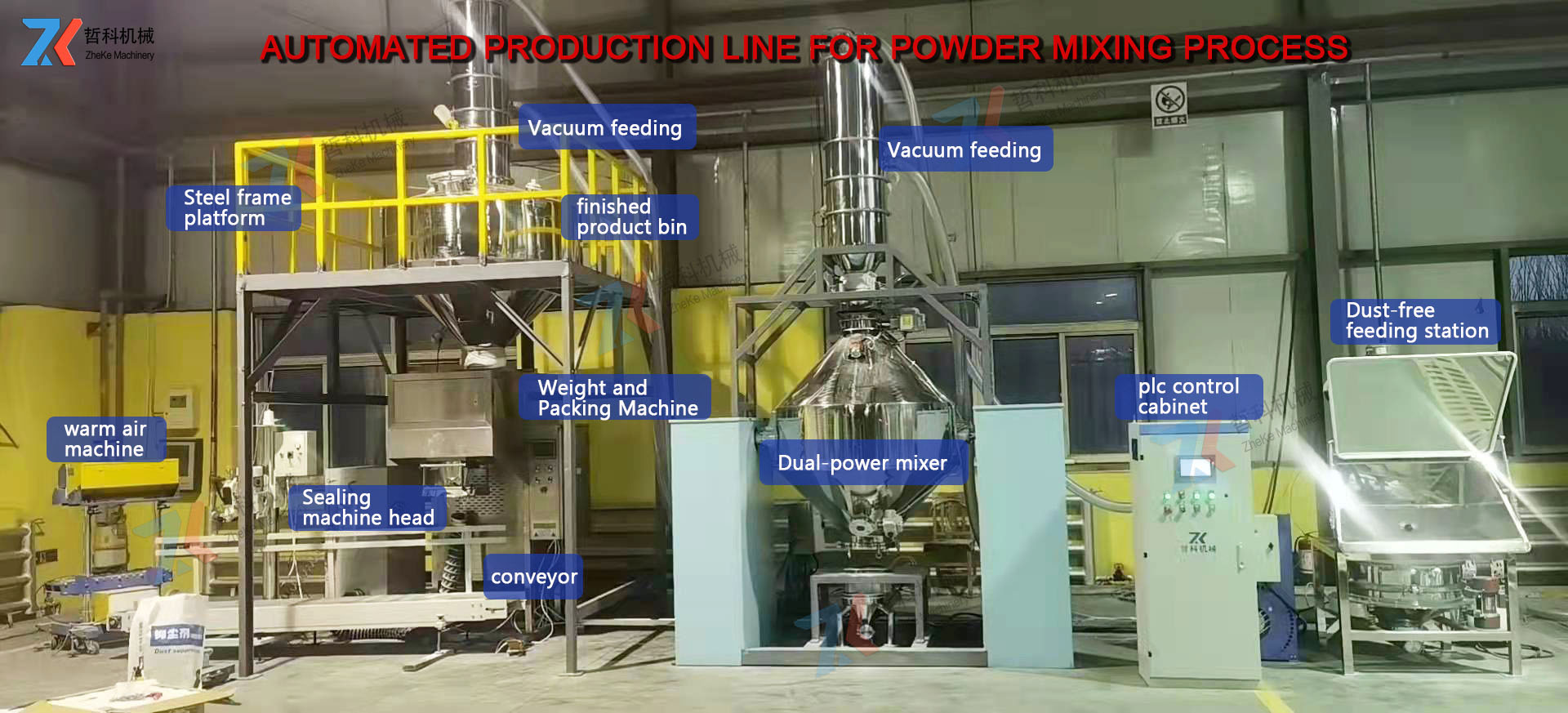

Previously, the customer learned about our company's MSJ dual-power mixer through the Internet and decided to conduct an on-site inspection. After a more in-depth understanding of the model, structure and technical parameters of the dual-motion mixer in our company, it was decided to order our MSJ1000L powder automated production line. This production line includes dust-free feeding, vacuum feeding, efficient mixing, intelligent unloading from the silo, and dust-free packaging. The entire hybrid automated production line has achieved seamless integration, with no floating dust and dust recovery, ensuring the entire workshop is clean and free from dust pollution.

Finally, the project was installed and debugged in December and put into production. The entire mixing production line adopts automatic control. The dust-free feeding station is used for feeding, which is convenient and fast, clean and free of dust pollution. The vacuum feeding machine is also convenient and fast for feeding. When feeding, the mixer automatically aligns and seamlessly connects with the feeding machine. After feeding is completed, the mixer automatically closes the valve and starts mixing according to the set time. When the time is up, the mixer automatically stops, and the outlet automatically aligns with the bottom and seamlessly connects with the bottom to form a closed channel. The materials automatically flow into the conveyor and are transported to the finished product silo. The packaging machine automatically weighs and performs sub-packaging. It is conveyed by the conveyor belt to the packaging machine for packaging. The entire automated production line adopts a closed structure to prevent dust from flying, ensuring that product quality meets standards and specifications are uniform. This significantly enhances production efficiency and reduces labor consumption.